During 2021, Plastron worked with air modelling experts at Southampton University to develop an advanced air management system for our spacecraft processing environments.

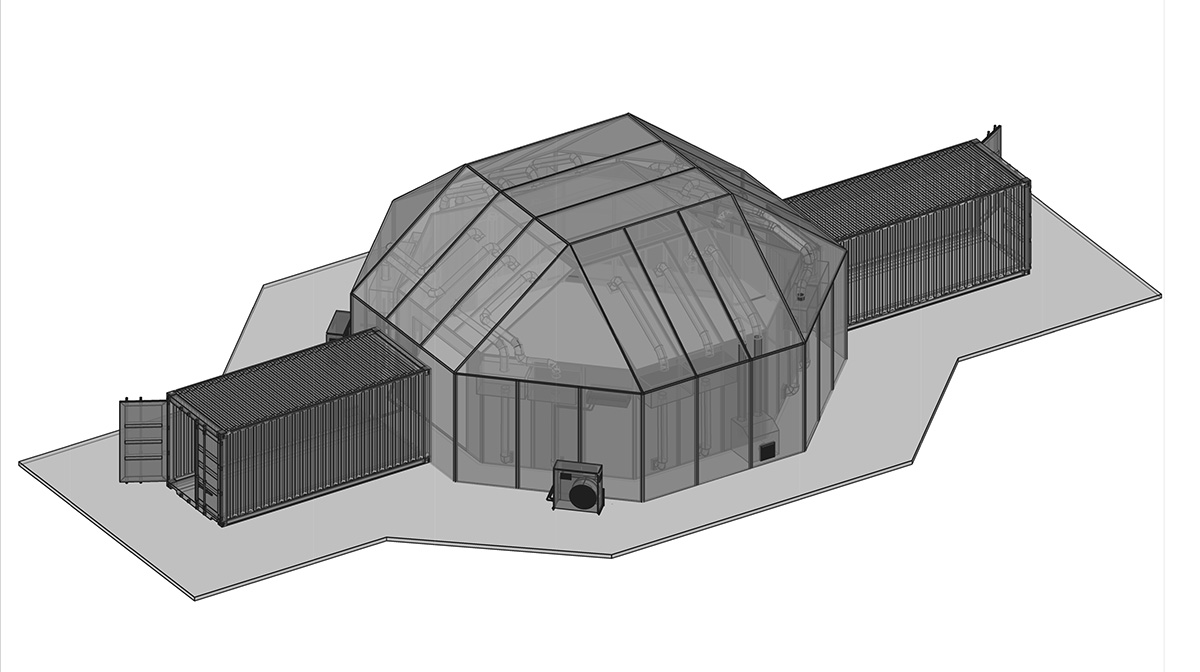

The Plastron facility was designed in line with the needs and mindset of the NewSpace sector, with the entire design relying on commercial OTS technology. This means the facilities not only have a proven design, but the effort – including carbon footprint – required for their development has been significantly reduced.

In this regard, however, we were aware of the importance of a high-quality air management system, which in general terms is appreciated by the industry, but not understood at a technical level, especially when energy conservation and environment optimisation is considered.

So, our work with colleagues at Southampton University, we took the OTS air management hardware and evolved air flow control in the working environment. This has enabled us to achieve a highly efficient system that aligns with ECSS cleanroom standards

So, for an operational volume of some 400 cubic metres with a height of 4.5m and a diameter of 9.5m, our cleanroom can establish an ISO8 environment from atmospheric particulate levels (400ppm) within six minutes! Compare this to the clean down times for conventional clean rooms, which can take up to 72 hours.

This project was supported with funding from the Sprint programme and their report on our project can be found here.